Selling Best Toilet Tissue Paper Making Machine Toilet Roll Manufacturing Machinery Product

Package size per unit product 8000.00cm * 5000.00cm * 2000.00cm Gross weight per unit product 5000.000kg small toilet ti

Basic Info

| Model NO. | paper machine |

| Embossing Roller | Steel Roller |

| Toilet Paper Type | Without Core |

| Function | Multi-Function |

| Constitute | Rewinding Machine Cutting Machine Packing Machine |

| Transport Package | Wooden Case |

| Specification | 10m*5.5m*2.5m |

| Trademark | "cailun" or custom |

| Origin | Hebei, China |

| Production Capacity | 20 Sets Per Year |

Packaging & Delivery

Package size per unit product 8000.00cm * 5000.00cm * 2000.00cm Gross weight per unit product 5000.000kgProduct Description

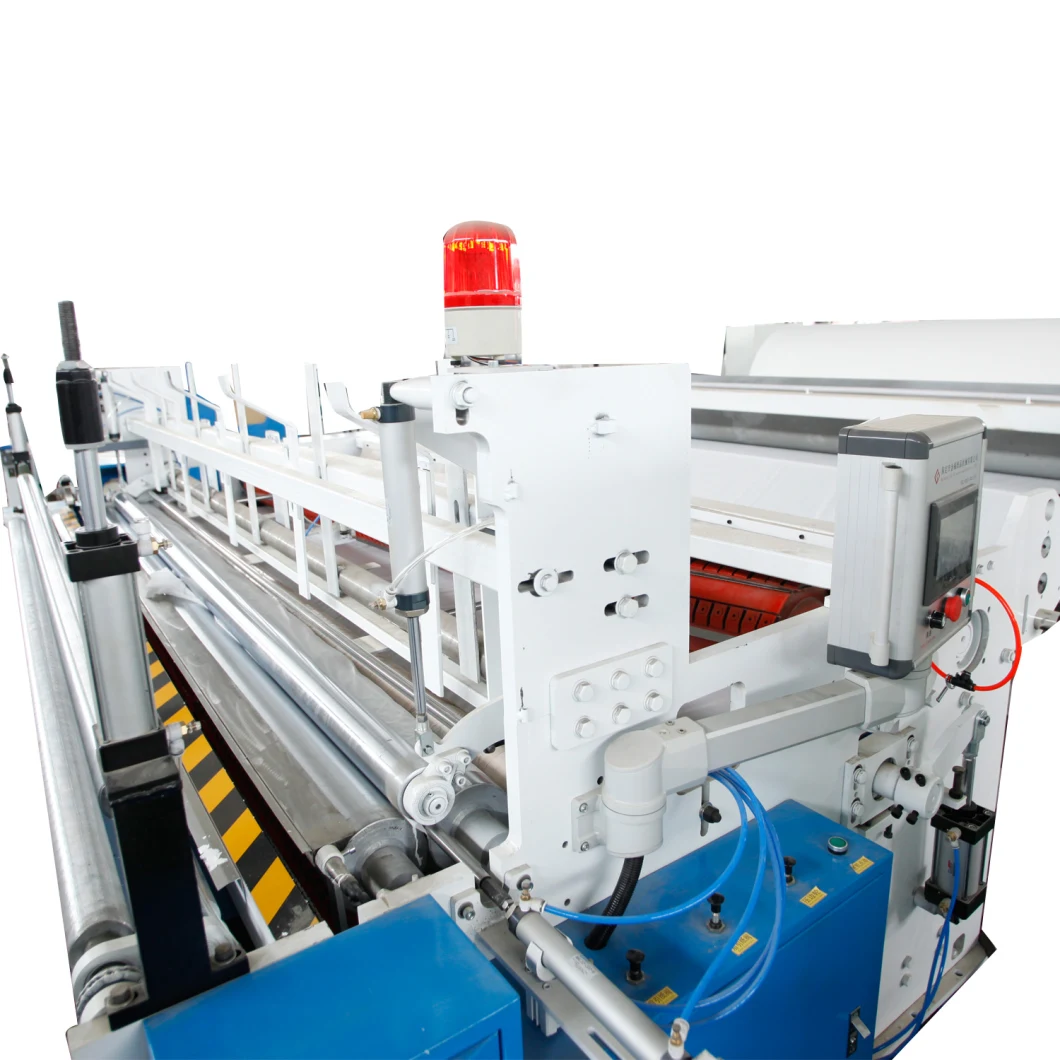

small toilet tissue paper embossing rewinder machine with PLC

This machine can rewind the jumbo toilet roll into small roll with various smaller diameters in accordance with need.

It doesn't change the width of jumbo roll,then ,the smaller diameter toilet roll can be cut into different size small toilet roll.

It adopts international new PLC computer programming technology (system can be upgraded), frequency control, automatic electronic brake. The touch-type human-machine interface operating system uses a coreless rewind forming system. application the PLC program wind column forming technology achieves the characteristics of faster rewinding and more beautiful molding.

| 1. Raw material width: less than 1900mm. |

| 2. Raw material diameter: up to 1100mm. (>1100 to order) |

| 3. Raw material core: 76.2mm (3 inches). |

| 4. Ejection frame: One layer of single belt, pneumatic auxiliary feeding. |

| 5. raw material requirements: 12 ~ 20g / mm wood pulp paper or straw pulp paper, one to three layers. |

| 6. Control mode: Frequency control, jog feed. |

| 7. Speed requirement: The maximum speed is 700 sheets/min with the count, and the normal production speed is 650 sheets/min. |

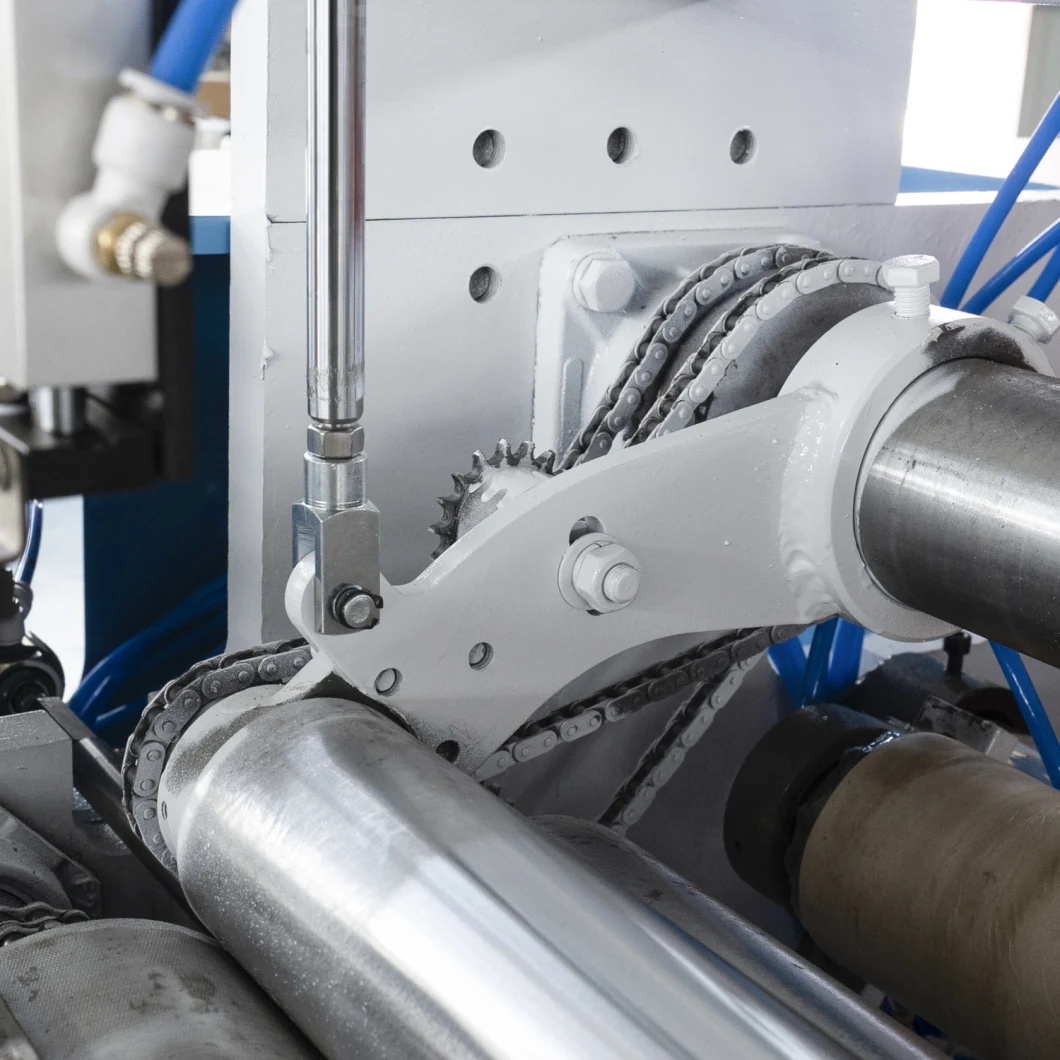

| 8. embossed form: steel on the rubber (steel roller point to flat, point to point, steel to steel, need to order) |

| 9. Frame form: The steel plate is bent and formed, and the screw is connected and assembled. |

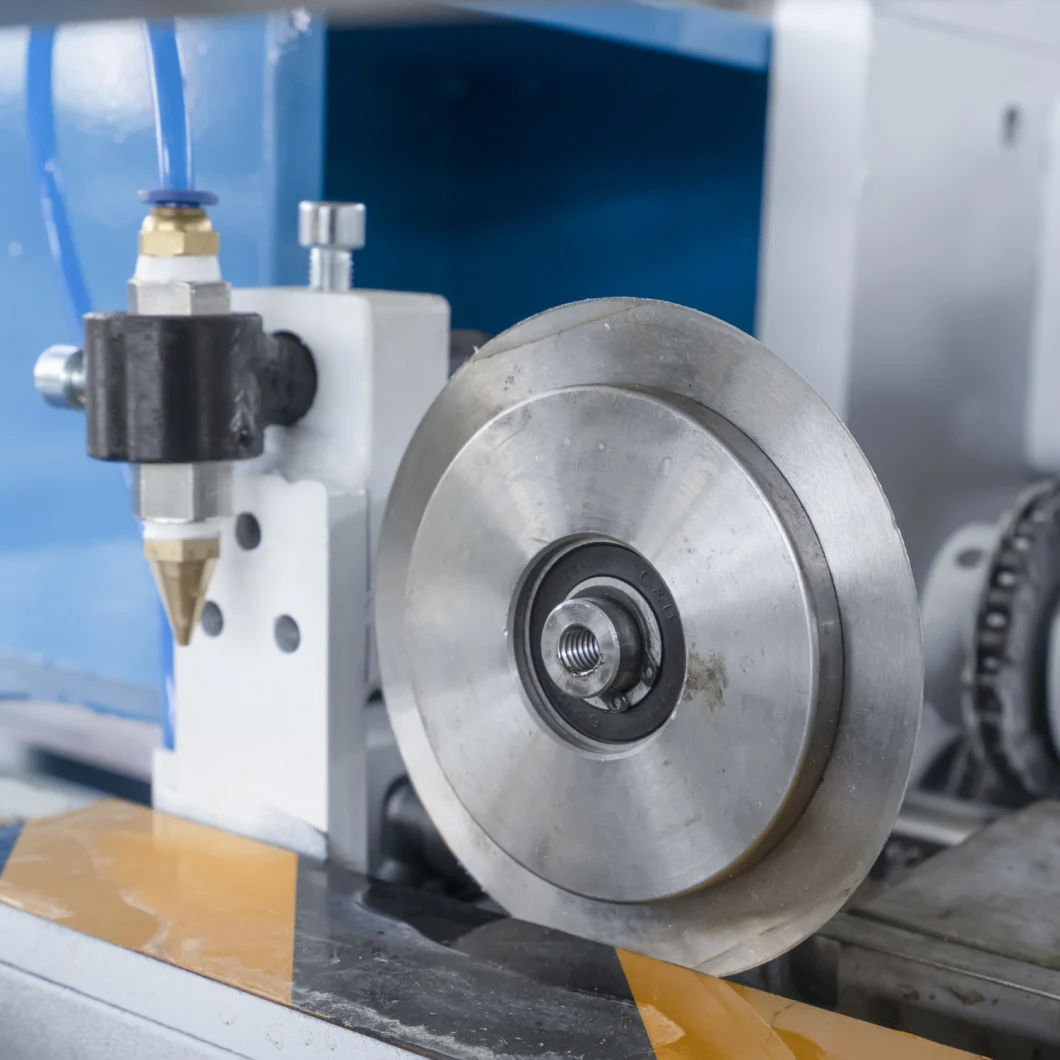

| 10. Transmission mode: Gear and synchronous belt drive. |

| 11. counting form: electronic pneumatic points. Step |

| by |

| step points (one or a group of independent adjustments). 12. molding method: mechanical. Foldable 1/4, 1/6, 1/8 fold |

| 13. the host power: 1.5 KW 14. Dimensions: 3.5x1.1x1.7 (length x width x height) Unit: meter |

1.This model is designed with computer control system, fully automatic in production process, the function is complete and the production speed is high.

2.It can automatically change the core, spray the glue and seals without stopping the machine and also automatically raise and lower speed when exchanging the core.

3.When change the core, the machine will be tight first and loosen later to avoid dropping off the roll core. 4.Equipped with automatic alarm to indicate filling up of core pipe. The machine will be automatically stopped when there is no core pipes.

5.Automatic alarm for breaking off of paper.

6.Equipped separate tension control for each unwinding jumbo roll. 7.It is convenient to change the feature to produce any other core pipe winding. 8.Left paper remind after sealing of product for convenient use.Hebei Cailun Machinery

HeBei CaiLun Machinery established in 2019. Our company can do all the businesses,which including research and creating,manufacture and sales.With these,the company can keep informed on market trends and requests.We supply our customers the whole production line from the low-grade to high -grade ,to meet different customers' demands.We have been professionally manufacturing toilet paper making machine, jumpo roll machine, handkerchief processing machine, napkin paper machine, facial tissue machine,kitchen paper machine and so on. We offer reasonable price, best service and best quality for both domestic and overseas customers. Our products are exported to Europe, the Middle East, South America, North America, Asia, Africa and all over the world. We're expecting to work with enterprises from all over the world and we're willing to research cooperative opportunities and trying to build a long-term and stable business relationship. We sincerely welcome companies worldwide to contact us for the future cooperation.

FAQ

Q: What should i provide if i want a quotation?

A: Dear Sir/Madam,Thanks for your interest in our paper making machine. In order to recommend proper machine and make detailed technical proposal and exact offer for you as soon possible, could you please tell us the following technical parameters? 1.what kind of paper do you want to produce?

Jumbo roll? Small toilet paper roll? Napkin paper? Kitchen towel paper? Facial tissue? or something else 2.what kind of raw material you will use?

(1)100%waste paper?

(2)waste paper virgin pulp?

(3)wheat straw,bamboo,wood,bagasse,reed? 3.how many tons do you want to produce per day(in 24hours)? 4.do you have requirement about paper width of jumbo roll(mm)? 5.what is the output paper weight(thickness)?

Q: Can you make paper factory design for me? I also need installation and training workers service.

A: Yes. please tell us the size and shape of your land or workshop,we can make a detailed factory layout drawing accordingly. The engineer overseas service available, we can send engineers to guide your installation, and train your workers.

What we can do for you:

Send to us