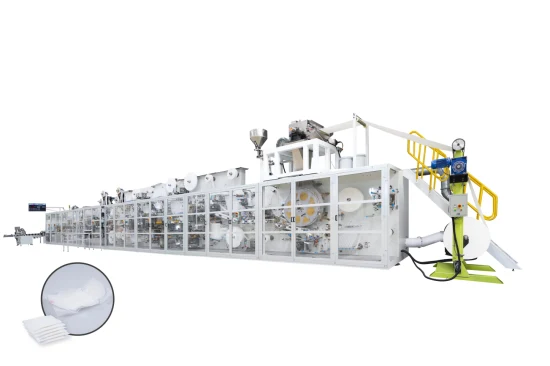

New Design Women Sanitary Pad Making Machine Sanitary Napkin Machine Price

New Design Women Sanitary Pad Making Machine Napkin Machine Price one station service, create value for you ,

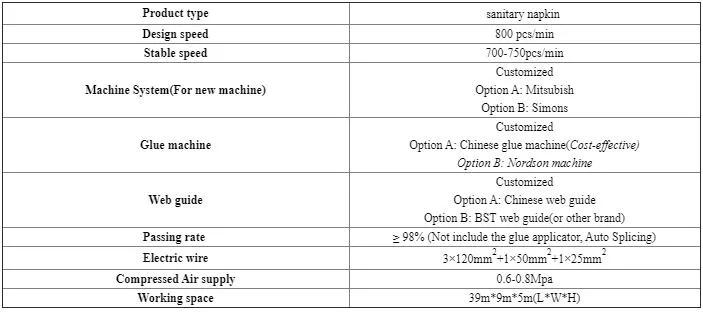

Basic Info

| Model NO. | TPM-SNM-27 |

| Warranty | 1 Year |

| Type | Drum Type |

| Real Running speed | >800PCS/min |

| Automatic Grade | Automatic |

| Certification | CE |

| Condition | New |

| After-sales Service | Available |

| Color | Customized |

| Operator | 8-10 |

| Voltage | 380V 50Hz |

| Core Components | PLC, Pressure Vessel, Engine, Motor |

| Weight | 40t |

| Manufacture Time | 120 Days |

| Transport Package | by Sea |

| Origin | China |

Product Description

New Design Women Sanitary Pad Making Machine Napkin Machine Priceone station service, create value for you

- Full Servo Design, No-shaft driving, modular structure, easy operation and maintenance, while the system can be updated for customer's reasonable requirement.

- Machine is designed under CE standard and approved by CE license, while the electric parts are with CE certificate already. Safety door and emergency stop button are mounted, also.

- Full-Servo Auto-control system, the automation is high.

- Interface adopted specialized industrial computer, humanized design and easy control, real-time data collection and alarm warning.

- Main raw materials auto unwinding by Servo motor with buffer tension balance for zero-time splicing, one button touch for shifting motor running direction.

- Auto Rectifier system adopted for main raw materials to increase the acceptance and performances of finial product

- Relative defects auto rejecting.

- Rear driving is transferred by time belts and time wheels, universal couples are adopted for main parts.

- Integration vacuum conveyor is more guaranteed and easy adjustable for belts and products positions, One side unload design for easy part-changing.

- All phase auto tracking.

- Main mechanical parts made by CNC, main purchased parts from world famous brands.

- Auto adjusting temperate as to set parameters for those electrical thermo parts.

- All short cutting are scratch mode, and relative rollers have surface treatment to avoid glue conglutination.

- Many other optional parts can be considered as to actual requests.

Send to us