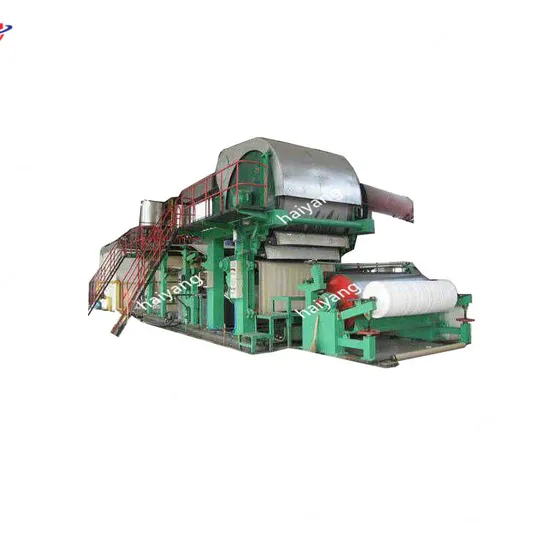

Customized Full-Embossing Felt Roller Packing Packaging Napkin Cutting Tissue Paper Making Machine

Basic Info

| Model NO. | 3200mm |

| Embossing Roller | Felt Roller |

| Toilet Paper Type | Without Core |

| Function | Rewinder |

| Processing Type | Toilet Paper Making Machine |

| Applicable Industries | Manufacturing Plant |

| Brand Name | Haiyang |

| Trimmed Width of Paper | 2800mm |

| Performance | Good Quality and Excellent Performance |

| Gauge | 3800mm |

| Capacity | 10t/D |

| Design Speed | 120-150m/Min |

| Work Speed | 180m/Min |

| Transport Package | Wooden Packing |

| Specification | 2950*1320*1500mm |

| Trademark | Haiyang |

| Origin | China |

| HS Code | 843920000 |

| Production Capacity | 5sets/Month |

Product Description

Product Description

Technical parameter

1.Raw material: bagasse

2.Output paper: toilet/tissue paper roll

3.Output paper weight: 13-40g/m2

4.Capacity: 20-25 tons per day

5. Net paper width: 2800 mm;

6.Rail gauge:3800mm

7.Drive way: Alternating current frequency converter speed control, sectional drive.

Click the machine model you want and get more information. Or you can send inquiry directly!

Machine type | Cylinder mould machine and fourdrinier machine | |||||||||||

Jumbo roll width (mm) | 787 | 1092 | 1575 | 1760 | 1880 | 2100 | 2400 | 2640 | 2850 | 2880 | 3200 | |

Capacity (t/d) | 0.3-1 | 1-3 | 3-5 | 5-8 | 8-10 | 10-15 | 15-20 | |||||

Paper grammage (gsm) | 13-40 | |||||||||||

Raw material | ||||||||||||

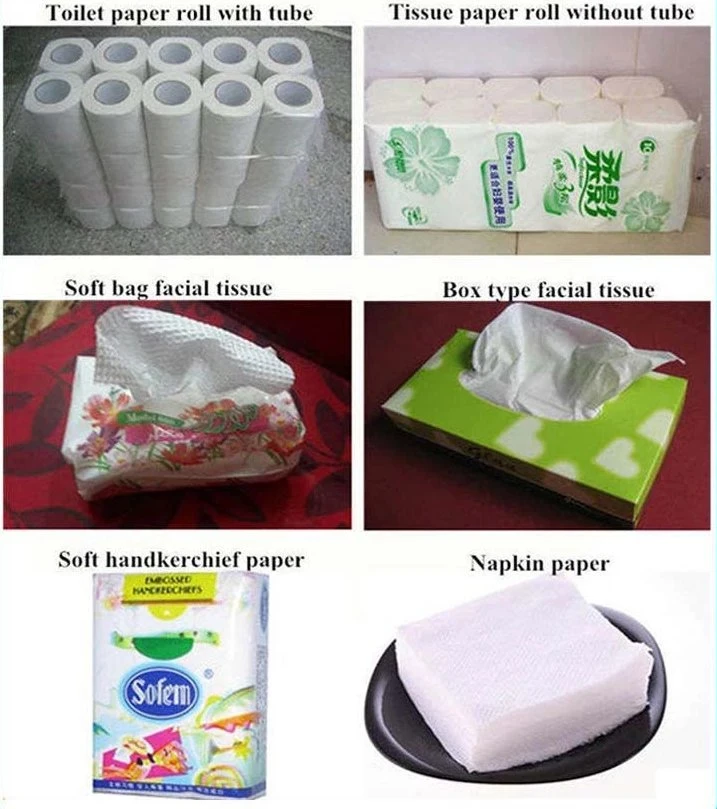

Finished product | Small toilet paper roll, napkin tissue paper, kitchen towel | |||||||||||

Model | 1092 | 1575 | 1760 | 2200 | 2500 | 2800 | 3000 | 3200 |

Max Width of Raw Paper | 1300mm | 1800mm | 2000mm | 2200mm | 2500mm | 2800mm | 3000mm | 3200mm |

Outer Dia. of Raw Paper | 1200mm (Other size to be specified) | |||||||

unwinding stand | 1-3 Stands (The Qty. of raw paper rolls to be specified) ( To be ordered) | |||||||

Inner Dia. of Raw Paper Core | 3 inches(76.2) (Other Size need order) | |||||||

Data setting | Human-machine interface(the touching screener is optional.) | |||||||

Programming Controller | PLC | |||||||

Braking | Electronical / pneumatic | |||||||

Machine Speed | 0-200m/per minute | |||||||

Operating Speed | 0-180m/per minute | |||||||

Outer Dia. of Finished Product | 90-135 mm (Other Size to be Specified) | |||||||

Dia. of Finished Product Core | 25-50m | |||||||

Dia. Control of Finished Product | Electronical / pneumatic | |||||||

perforating | 4 pieces of circular soft knives,the distance is 108±2mm(Other Size to be Specified) | |||||||

Perforating distance | Adjustable | |||||||

Pneumatical System | Air Compressor, minimum pressure 5kg/cm2pa(offered by customers) | |||||||

Control Voltage | regulated power DC24V(for your reference ,need order) | |||||||

Main Machine Structure | Wallboard type | |||||||

Mainframe Transmission | Stepless gear-box | |||||||

Move Mode | Synchronous Belt | |||||||

Main Transmission | conversion adjusting 5.5-22kw | |||||||

Optional function | ||||||||

Perforationknife | 4 knives :the distance is 90-140mm | |||||||

2 knives: the distance is 200-350mm | ||||||||

1 knife: the distance is200-500mm | ||||||||

Perforatingcontrol | Pneumatic | |||||||

Embossment | Single Embossing,Double Embossing ,Steel to Steel Embossing ,Pneumatic Embossing (To be Ordered) | |||||||

Side Rolling Embossment | Independent Pneumatic | |||||||

Gluing and Laminating | kitchen paper towels: Gluing form point to point or point to the whole surface of the paper | |||||||

Color glue tissue roll | ||||||||

| No. | Name | Function |

| 1 | Stainless steel cylinder mold | Extract the pulp fiber to felt |

| 2 | Alloy dryer cylinder | Dry the wet paper |

| 3 | Double-layer dryer hood | Cover dryer and collect the hot&moist air diffused by dryer |

| 4 | Axial-flow ventilator | Ventilate and pull out the hot&moist air in the exhaust hood |

| 5 | Roots vacuum pump | Provide vacuum force for suction box |

| 6 | Air compressor | Provide compressed air for pneumatic devices |

| 7 | Frequency conversion controlling cabinet | Control the speed of the machine |

| 8 | Vacuum suction box | Absorb water contained in the wet paper |

| 9 | High concentration hydrapulper | Break the waste paper into pulp |

| 10 | High frequency vibrating screen | Separate and remove large impurity in the pulp |

| 11 | Impeller | Stir pulp and keep pulp well-mixed with water |

| 12 | Pressure screen | Getting ride of impurities |

| 13 | Bleacher | Bleach and whiten pulp |

| 14 | Double disc refiner | Grind, refine and fibrillation |

| 15 | Low concentration sand remover | Remove sand and impurities |

| 16 | Pulp pump | Pulp transportation |

| 17 | Electrical operation cabinet | Control machine operation |

| 18 | Boiler | Provide steam for the drying section |

Pulp machine equipment:

Finished product:

Paper machine equipment:

| Company profile: |

| Qinyang Haiyang Paper Machinery is a professional manufacturer of papermaking equipment.The company is located in Xili industrial district, Qinyang City, Henan province.It was founded in 1990.There are more than 100 employees,covering 1200sq.m.The company's leading products are 787-3800mm series toilet paper machine,1575-4800mm cylinder paper machine,fourdrinier wire paper machine,superimposed wire paper machine, pulping equipments and further processing equipments.We can also provide paper mill renovation and renewal programs and service.fourdrinier multi-cylinder kraft paper making machinefourdrinier multi-cylinder kraft paper making machineA workman must sharpen his tools if he is to do his work well.High quality products need advanced equipment to achieve.Our company now own 4 manufacturing workshops,35 CNC machining equipments,26 professional technicians,20 engineers,which effectively guarantees the accuracy and performance of the products.Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. |

| Our service: |

Pre-Sales Service | After-Sales Service |

| How to get your suitable machine and production lines?1.Inquiry:contact us by email,phone,wechat etc.2.Communication:after getting our quotation,you confirm the paper machine model and specify the items you desire.3.Contract:place order and signing the agreementfiles.4.Production:as soon as we received first payment,we will start to produce machines.we will notify client to book the ship 15days in advance.5.Delivery: all the machines will be shipped according to contracted items.6.Installation:we will send engineers/technicians to install the whole production line. | 1. Our company view adhering to the "excellent quality, customer satisfaction" service concept,to provide you with excellent products and perfect service.2. Our company keep the contract and reputation. Quality first, products guarantee one year, as it is quality problem,free replacement.3. For every purchase of our company's products, the company can send technicians to guide the installation and debugging, and can undertake the design of process and equipment installation. |

| FAQ: |

| 1.Are you trading company or manufacturer?We are manufacturer,and we produce all kinds of paper making machine to meet your demands.2.How could i choose right paper making machine?When ordering ,please specify the raw material,trimmed width,and capacity you want.3.How long is guarantee period for paper making machine?12 months after formal operational.4.What is the delivery time if we make a order from you?Usually,the delivery time for smaller machines is 30-45 days after receiving deposit,but for bigger machines,it will be longer to make sure the equipment quality.5.What is your payment terms?T/T(telegraphic transfer)30% as deposit,and 70%balance paid before shipment.6.How is the quality of your equipment?(1).We have enough practice/experience.To keep and develop our good reputation,we couldn't allow the unqualified machine,as well as you.(2).We have a technician team of engineers and experts.They mainly research the advanced paper making technology,to make sure our machines' design are newest.(3). The machines will be pre-installed at workshop before delivery.(4). All of our machines has audited the certificate of SGS.7.Why your price is higher than other similar supplier?Different quality,different price.Our price is matched with our high quality.Compared with other suppliers based on the same quality,our price is lower.But anyway,to show our sincerity,we will give you some discount.8.Can we visit your factory and the running machine has installed in China?Welcome to visit our factory.You can check our production ability,processing ability,check our facilities and running paper production line.What is more,you can discuss with engineers directly,and learn the machines well. |